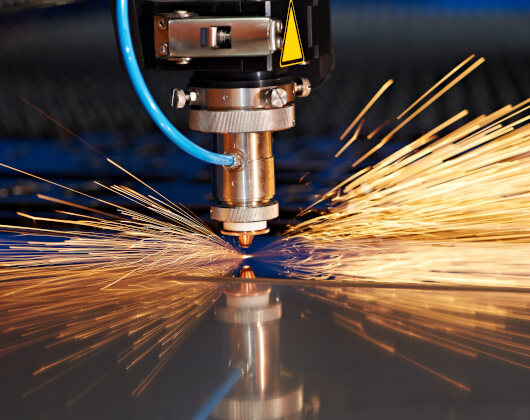

Our machinery park, which includes 5 lasers and a punching machine, allows us to precisely cut out complex elements from steel sheets (black and stainless), aluminum, plexiglass, plywood, cardboard, felt, rubber, textolite and many other materials. The laser head positioning with the accuracy up to thousandths of a millimeter allows us to cut parts with high precision.

Phone number

+48 881 510 550

+48 533 173 033 EN

Opening hours

Mon - Fr: 6 am - 2 pm

info@flomar2.com

Services

We cut out the elements with high precision using lasers and punching machines!

State-of-the-art cutting process

Use of lasers

Different parameters of Trumpf and Kimla lasers allow us to cut details from sheets of different parameters. The maximum size of the sheet from which we cut out the elements is 2 x 6 m! The maximum thicknesses of the cut out parts is: 20 mm for black steel, 15 mm for stainless steel and 10 mm for aluminum. Our laser dedicated for cutting plastic, we cut out even 70 mm thick plexiglass parts!

Cutting out using a punching machine

We use the Euromac punching machine for metal sheets up to 2.5 mm thick. It is irreplaceable when it comes to punching holes. Making holes in sheet metal using a punching machine does not cause the workpieces to heat up, so there is no stress in the cut piece. The punching machine is not only about perforations but also about cutting out non-standard shapes and embossing. The sheet metal positioning accuracy is of the same class as in the case of laser cutters which translates into the precision of the cut parts.

Over 10 years of experience in using lasers puts us at the forefront of service companies in Poland, and state-of-the-art equipment allows us to shorten the time of order completion as much as possible!

+48 792 510 580 EN