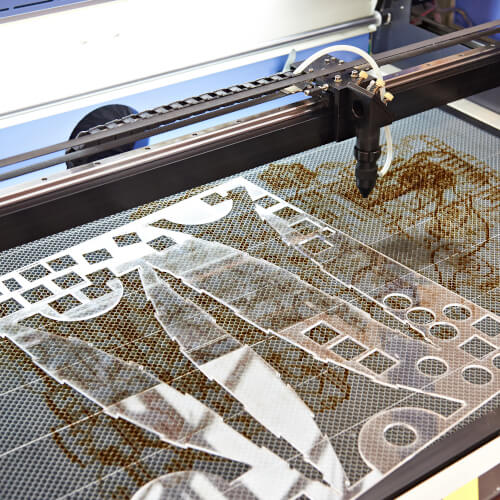

Our company uses a laser cutter with a working area of 2030 × 3050 mm. Thanks to modern solutions, we are able to create any shape of a plastic element cut and the cut of materials such as cork, plywood, rubber, textolite, cardboard and many more!

Phone number

+48 881 510 550

+48 533 173 033 EN

Opening hours

Mon - Fr: 6 am - 2 pm

info@flomar2.com

Services

Laser cutting of plastics and other materials

Modern and precise Carbon Pro 2030 LM laser cutting machine

Laser cutting is characterized by very high accuracy and in the case of elements with a thickness of up to 2 mm, we can achieve an accuracy of 0.2 mm.

The production and services performed so far included:

Laser cutting:

- 60mm thick plexiglass,

- 20mm thick plywood,

- 1mm thick textolite,

- 20mm thick cardboard,

- 5mm thick rubber.

Engraving:

- glass,

- ceramic tiles,

- mirrors,

- cartons,

- plexiglass,

- plywood,

- stainless steel.

After a consultation, we offer the laser cutting of elements from the following materials:

- laminate,

- synthetic material,

- foam sponge.

The years of experience with laser cutters and an unconventional approach of solving problems place us at the forefront of companies offering plexiglass processing.

Bending of plexiglass elements

Reliable and modular GT2080 plexiglass bending machine

We offer bending of plexiglass elements. We bend plexiglass with a maximum length of 1990 mm and a maximum thickness of 20mm. The bending process involves local heating of the material until it becomes ductile, then the detail is bent manually or by the usage of a matrix to obtain the required angle and dimensions.

8 resistance wires, with the arrangement that can be determined almost with no limits, allows us to perform up to 8 bends in one detail during a process of heating a plexiglass element (it depends strictly on the thickness and size of an element). The work capacity of bending dies enables the bending process to be repeatable and maximally accelerated for large batches of elements.

Bending of plexiglass elements is widely used in making business cards cases, leaflet stands and furniture finishing elements.

Machining of plexiglass and soft metal edges

We use the BERMAQ AMI-C edge milling and polishing machine

We also offer the processing of straight outer edges of plexiglass and soft metal details. With the help of an automated milling-polishing machine, we can process details up to 3100mm long and with a maximum thickness of 120mm.

Using various cutting tools, we are able to polish or dull the edges of plexiglass, aluminum and copper. Working range up to 120mm thick and special pneumatic clamps make that the several details can be processed in one pass of the tool!

The adjustable cutting head can work in the range of -5º to + 60º (obtained 30º sharp angle) which allows to obtain precisely chamfered edges not only at right angles. Finally, we can get a detail that its every edge can be polished at a different angle and in the selected finish quality.

Plexiglass edge chamfering also allows for precise gluing of individual details, in places where bending is not possible or the customer’s requirements and expectations do not allow it.

Polishing the edges gives the details a perfect look from every side, so there are no traces of laser cutting on them.

+48 792 510 580 EN